Socket-weld flanges have a hole in the middle where a pipe can go. The pipe is held in place by a fillet weld on the outside of the flange hub. Because the weld is hard to prove, this type of flange is not considered a high-integrity joint. This means that socket weld flanges are only good for low to medium classes ( ASME 600). Because socket weld flanges are less strong and can't handle higher pressures, they almost always have flat or raised faces.

Socket-weld flanges have a hole in the middle where a pipe can go. The pipe is held in place by a fillet weld on the outside of the flange hub. Because the weld is hard to prove, this type of flange is not considered a high-integrity joint. This means that socket weld flanges are only good for low to medium classes ( ASME 600). Because socket weld flanges are less strong and can't handle higher pressures, they almost always have flat or raised faces.

|

|

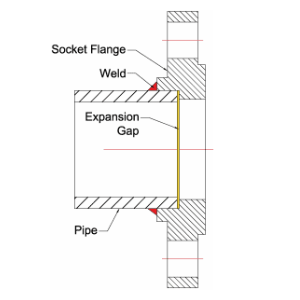

| Socket-weld Flanges Crossection | Socket-weld Flanges |

Socket weld flanges are made for small nominal pipe sizes ( 4 inches, 10cm) and are usually used for 12 to 2-inch pipe sizes (1.3 to 5cm pipe sizes). A socket weld flange has the same mechanical strength as a slip-on flange, but the slip-on flange may have two welds.

The ASME B31.3 standard says that there needs to be a gap of about 1/16 of an inch (1.5mm) between the pipe end and the socket. This gap allows for thermal expansion caused by welding and makes it less likely that the weld will crack. In practice, this means that the pipe should be pushed all the way into the flange and then pulled back by the amount you want (1/16 of an inch, or 1.5mm). This gap is shown in red on the image above.

The simple design of socket weld flanges is one of their best features. They work well for small pipe sizes, like 2 inches (5cm) or less, and for non-critical applications, like non-hazardous systems. However, they are not good for systems that are highly corrosive or erosive.

Non-Destructive Testing (NDT) Techniques

Socket weld flanges only have one fillet weld, and radiography can be used to prove the weld, even though it's not very useful. The weld can be checked with magnetic particle inspection (MPI) and dye penetrant inspection (DPI).

ASME Standards

According to the ASME B16.5 standard, socket-weld flanges are not required for ASME class 2500 ratings. ASME B31.3 says that there needs to be a gap of about 1/16 of an inch (1.5mm) between the pipe end and the socket.

Contact: Sino Special Metal Co., Ltd.

Phone: 86-19527792928

E-mail: sales@ssmsteel.com

Whatsapp:86-19527792928

Add: Mudu town Jinfeng South Road, Wuzhong District, Suzhou City, Jiangsu Province

We chat