welding neck, slip-on, socket weld, threaded, blind flange, and the lap joint.

Flanges are a way to connect pipes, fittings (like elbows, tees, and so on), and valves mechanically. Unlike welds, flanges are a type of joint that isn't permanent and can be easily put together and taken apart (ideal for systems that require maintenance). Flanges can be put on by welding, screwing, or lapping. After welding, these are the two most common ways to connect two pieces.

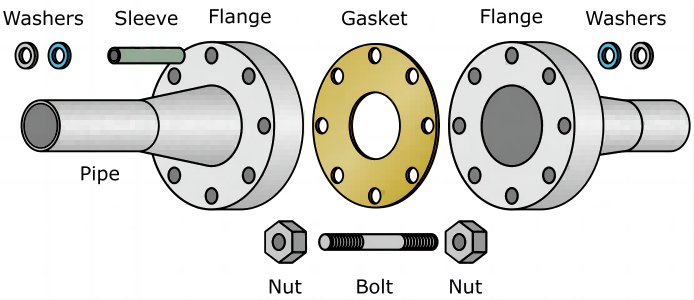

Flange (blade, hub).

Gasket (metallic, composite, or non-metallic).

Fasteners (nuts, bolts, or studs).

|

| Flange Assembly |

The "blade" and the "hub" are the two main parts of a flange.

The flange face and the area where the bolts go through the flange are both included in the flange blade.

The hub of the flange is where the pipe that goes through the flange fits.

Gaskets are used to make sure that the flanges don't leak between them. It is possible to connect two metal flanges without gaskets, but it is hard to seal and can only be done with flanges that are made for that purpose.

The end connection shows how the flange is attached to the pipe that goes with it (threaded connection or welded).

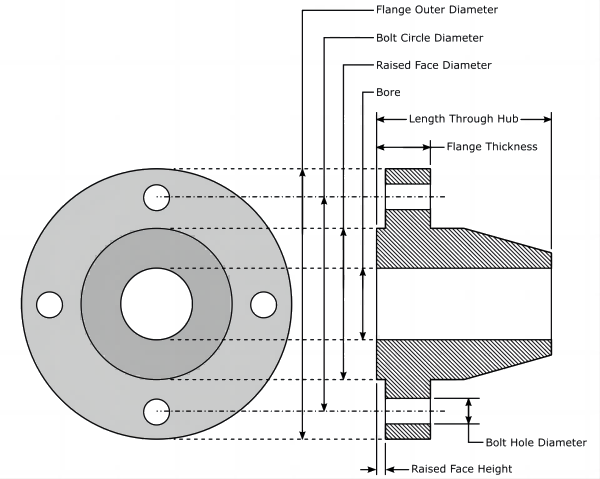

Because many terms, definitions, and phrases are used in the same way, flange terminology and nomenclature can be hard to understand. To make it easier to learn, readers should know what the following terms mean:

Flange types describe how a flange is made. Some types of flanges are welding neck, slip-on, socket weld, threaded, blind flange, and the lap joint. Flange types are chosen based on the required temperature and pressure and can be recognized by their shape.

|  |  |

| Welding Neck Flange | Slip-on Flange | Socked Welding Flange |

|  |  |

| Threaded Flange | Blind Flange | Lapped Joint Flange |

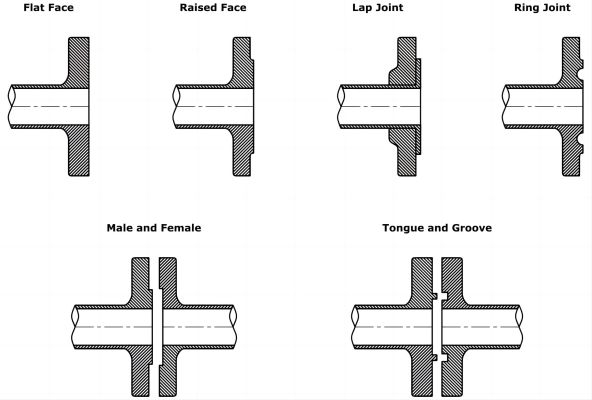

Flange faces are the parts of the flange that are used to seal it. Usually, a gasket is put between the two flange faces that face each other. There are many different kinds of flange faces, such as flat, raised, ring-type joint (RTJ), lap joint, tongue and groove, and male and female.

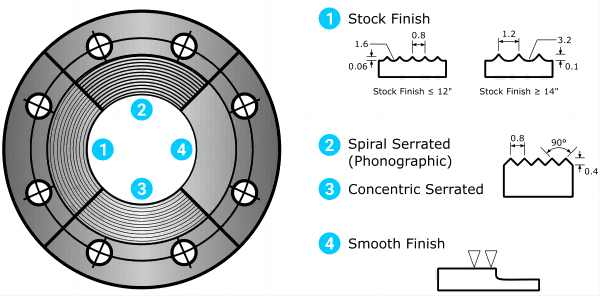

Flange surfaces illustrate the state of the sealing surface on the flange face. The face of a flange can be smooth, or serrated. Serrations are grooves that are cut by a machine into the face of a flange. Material from the gasket flows into the grooves, making the seal more reliable. The grooves also help keep the gasket in place. The smoothness of a flange face surface is defined by its Roughness Average (Ra) or Arithmetic Average Roughness Height (AARH).

It's important to know that there are many things that affect not only which type of flange is used for a certain application, but also which face and surface are used. For instance:

Some systems may need welded joints that can be checked easily (this is not always possible with certain flange types).

Some flange faces may not be good for systems with higher pressure because the maximum sealing pressure is too low (flat face designs).

Cast-iron flanges, for example, tend to have poor finishes that make the sealing surface rough. If a leak-proof seal is to be made, a gasket must be used on the rough surface.

When choosing a flange, the material is chosen first based on the process requirements, and then the temperature and pressure requirements are met based on the material chosen.

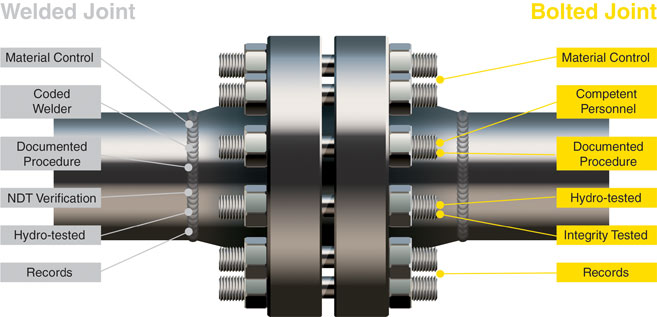

Flanges are one kind of bolted connection. There are also joints that are threaded and joints that are welded.

A flange and fasteners are needed for a bolted joint (nuts, bolts, or studs).

To make a threaded joint, you need a male screw thread and a female screw thread. The male screw thread screws into the female screw thread.

A weld is the process of melting or fusing metal together with heat. This is how a welded joint is made.

The type of joint used depends on a lot of things, such as pressure, temperature, the type of process fluid, how the system works, and the environment around it. If any of the following are true:

Other types of joints can't be used. For example, welding may not be possible in areas where there is a risk of fire or explosion (Ex areas). This is more of a problem for piping systems that are already in use than for ones that are being built.

A piece of machinery needs to be disconnected from the service line so that it can be fixed or replaced.

Simple hand tools are all that are needed for a quick assembly on the job site.

The tank, pipe, or machine to which the flange is attached must be maintained often. A flange is quick and easy to take apart and put back together, but a weld is not.

Some of the most important problems with a bolted joint are:

Insulating a joint that is bolted costs more than insulating a joint that is welded or threaded.

Threaded or welded joints take up less space than bolted joints.

Each bolted joint is another place where water can get in (even if assembled correctly).

As a general rule, threaded joints are only good for applications with low pressure and temperature, while bolted and welded joints are good for applications with higher pressure and higher temperature. If a threaded joint must not leak and a small amount of leakage is not acceptable, it can be seal welded. The seal welding method is only used when the service pressure is high. It is not the best solution because it creates a point of high stress that is more likely to break over time.

Non-destructive testing (NDT) techniques, such as penetrant testing, ultrasonic testing, magnetic particle testing, hydrostatic pressure testing, etc., can be used to show that a weld is good. It is harder to show that a flange and flange gasket are good.

A flange is made when two surfaces that face each other are pressed together on purpose to make a leak-proof seal. To make a seal, force must be applied and kept on each of the flange faces that are facing each other. Since many flange faces have manufacturing flaws (scratches, dents, pits, etc.), you need to put a gasket, which is a softer material, between the two sealing surfaces to make a seal.

Flanges are put into groups based on certain characteristics, and these groups are usually defined by standards and specifications for piping. What makes up a flange?

Type: The overall shape of the flange. There are different kinds of flanges, such as welding neck, slip-on, and socket weld.

Face: This is where the flange seals. There are different types of flange faces, such as flat face, raised face, and ring-type joint.

Standards and Specifications: Flanges are made to meet standards and specifications that have already been set. The size, shape, schedule, and material of a given flange are set by standards and specifications (to name a few factors).

Dimensions: How big the hub, face, blade, etc. of a flange are. Dimensions depend on the nominal pipe size (NPS) and the pressure class needed for a given application.

Nominal Pipe Size (NPS) is an unmeasured unit that tells how big the pipe, fitting, or other thing is that connects to the flange.

Pressure Class: The maximum amount of pressure and temperature that the flange can handle for a certain material. Even though it is called "pressure class," this factor depends on the material and temperature.

Material: The type of metal used to make the flange, such as cast iron, carbon steel, stainless steel, etc.

Schedule (SCH) is the thickness or wall thickness of a pipe. The schedule of a pipe only matters when welding neck and lap-joint flanges, because the schedule of these flanges must match the schedule of the pipe to which they are connected. The other types of flanges either partially slide into, screw into, or go all the way through their corresponding flanges. This means that the flange schedule does not have to match the pipe schedule. The schedule is important for flanges with swivel rings, but these aren't used very often.

Flange - ASME B16.36, Orifice Flange (1/2"-24")

Flange - Industry Standard Flange (also called Large Diameter Flange) (26"-larger)

Slip-on Flange: Class 300, Class 400, Class 600, Class 900, Class 1500

Threaded Flange: Class 300, Class 400, Class 600, Class 900, Class 1500

Weld Neck Flange: Class 300, Class 400, Class 600, Class 900, Class 1500, Class 2500

Blind Flange: Class 75, Class 125, Class 175, Class 250, Class 350

Welding Neck Flanges: Class 75, Class 125LW, Class 125, Class 175, Class 250, Class 350

Slip-on Flanges: Class 75, Class 125LW, Class 125, Class 175, Class 250, Class 350

AWWA C207

Steel Ring Flange: Class B, Class D, Class E, Class F

Steel Hub Flange: Class D, Class E

Blind Flange: Class B, Class D, Class E, Class F

ASME B16.1 - Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250

ASME B16.1 - Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250

ASME B16.5 - Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard

ASME B16.24 - Cast Copper Alloy Pipe Flanges and Flanged Fittings: Classes 150, 300, 600, 900, 1500, and 2500

ASME B16.36 - Orifice Flanges

ASME B16.42 - Ductile Iron Pipe Flanges and Flanged Fittings: Classes 150 and 300

ASME B16.47 - Large Diameter Steel Flanges, NPS 26 Through NPS 60

Contact: Sino Special Metal Co., Ltd.

Phone: 86-19527792928

E-mail: sales@ssmsteel.com

Whatsapp:86-19527792928

Add: Mudu town Jinfeng South Road, Wuzhong District, Suzhou City, Jiangsu Province

We chat