A fastener or fastening is a piece of hardware that mechanically links or attaches two or more items together. In general, fasteners are used to produce nonpermanent joints, i.e., joints that can be removed or disassembled without causing damage to the components joining them. Steel fasteners are often composed of stainless steel, carbon steel, or alloy steel.

A fastener or fastening is a piece of hardware that mechanically links or attaches two or more items together. In general, fasteners are used to produce nonpermanent joints, i.e., joints that can be removed or disassembled without causing damage to the components joining them. Steel fasteners are often composed of stainless steel, carbon steel, or alloy steel.

A bolt is a type of threaded fastener having an exterior male thread that requires a female thread such as a nut. Screws and bolts are extremely similar.

Bolts are instruments used to secure and fix the faces of assemblies using a nut. They are threaded and include a nut to match. The aim of bolts is to link aligned unthreaded holes by inserting them through the holes and securing them with the nut.

Structural bolts are manufactured in accordance with ASTM standards A563 and A194 and are used with hex nuts to join structural steel members. They are graded according to their size range, proof load, minimum yield and tensile strengths, and proof load. High strength bolts are classified as structural bolts due to their outstanding tensile strength and capacity to establish strong and tight joint connections. They can withstand greater torque, which is crucial for steel structures.

SAE Grade 9 structural bolts, often known as grade 9 hex cap screws, have the highest tensile strength of any structural bolt at 180,000 PSI. They are utilized in applications that demand heavy-duty bolts, such as manufacturing machinery and bulldozers. In addition, grade 9 structural bolts are made of yellow zinc chromate, making them resistant to corrosion.

A bolt primarily consists of the following components: Bolt Shaft, Bolt Head, Nut Device, Washer Component.

|  |  |  |

| Bolt Shaft | Bolt Head | Nut Device | Washer Component |

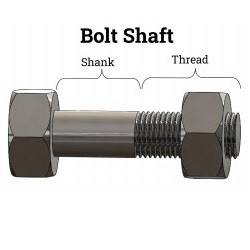

Bolt Shaft

The shaft is a cylinder that supports the shear stresses exerted on the bolt and prevents the pieces from moving radially. The bolt shaft consists of two segments:

The shank (or body) of a bolt is the unthreaded section beneath the head. The length is measured from the head to the beginning of the thread transition. When the shank is inserted into a bolt hole, it provides a precise and smooth contact. This part distributes stress more evenly than the threaded portion. Consequently, the shank must be extended until it surpasses the interface of the fastened materials.

The probability of bolt loosening increases if the attached parts produce or are subjected to vibration. If a bolt lacks a shank (i.e., if the bolt shaft consists solely of threading), the vibration may drive the connected pieces apart.

The thread is the continuous helical ridge on the bolt shaft's outside. This piece fits the nut and allows the bolt to be inserted or extracted from the components. The bolt thread joins with the nut's internal threads to form a fastened connection. All bolts must have a threaded portion, yet the majority of shafts are only partially threaded.

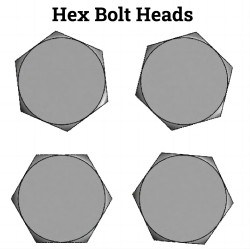

Bolt Head

The head of the bolt is responsible for carrying the axial stresses that hold the materials being secured together. A wrench or driver imparts adequate torque to the bolt head in order to tighten or loosen it. Numerous profiles and varieties of bolt heads exist, including:

Hex bolt heads have a six-sided hexagonal head that can be grasped by a variety of tools (e.g., wrenches).

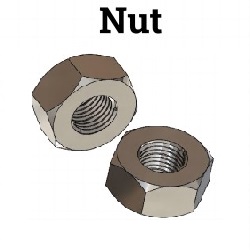

Nut Device

The female component of a bolted joint with a threaded hole is the nut. To keep numerous components together, it produces clamping force and prevents axial movement. Combining two forces secures the components. The axial force that compresses the fastened pieces is exerted by the nut. This axial force generates friction between the bolt and nut threads, preventing the bolt and nut from unscrewing. If the parts are exposed to extended and continuous vibration and impact, mechanical locking devices (e.g., lock washers, jam nuts, and split pins) and thread-locking fluids are utilized.

Washer Component

The washer is a thin, flat plate with a hole in its middle. Typically, it is positioned between the bolt head and the nut. Its principal purpose is to distribute the load of the threaded fastener over a greater surface area. Thus, the deformation of materials that are fastened is prevented. Washers constructed from softer materials such as plastic, rubber, and urethane can effectively dampen vibration and prevent threads from becoming loose. There are particular varieties of washers that prevent liquids from entering the bolt joint; these types contribute to the formation of a watertight seal.

Types of Bolts

There are many different types of bolts, each having different characteristics that make them suitable for use across a wide range of applications. The principal types of bolts commonly used include: Anchor Bolts, Blind Bolts, Carriage Bolts, Double End Bolts, Eye Bolts, Flange Bolts, Hex Bolts, Machine Bolts and Machine Screws, Penta-Head Bolts, Round Head Bolts, Shoulder Bolts, Socket Head Bolts, Square Head Bolts, T-Head Bolts, U-Bolts.

|  |  |

| Anchor Bolts | Blind Bolts | Carriage Bolts |

|  |  |

| Double End Bolts | Eye Bolts | Flange Bolts |

|  |  |

| Hex Bolts | Machine Bolts and Machine Screws | Penta-Head Bolts |

|  |  |

| Round Head Bolts | Shoulder Bolts | Socket Head Bolts |

|  |  |

| Square Head Bolts | T-Head Bolts | U-Bolts |

Contact: Sino Special Metal Co., Ltd.

Phone: 86-19527792928

E-mail: sales@ssmsteel.com

Whatsapp:86-19527792928

Add: Mudu town Jinfeng South Road, Wuzhong District, Suzhou City, Jiangsu Province

We chat