Diameter: 12-point screws are available in various diameters, ranging from #0 to 3 inches or more. The most common diameters for 12-point screws are between 1/4 inch and 1 inch.

Length: 12-point screws come in different lengths, depending on the application. They can range from 1/2 inch to 24 inches or more.

Material: 12-point screws can be made from different materials, including steel, stainless steel, brass, and titanium. The choice of material will depend on the application, as some materials offer better corrosion resistance or strength than others.

Thread type: 12-point screws can have different thread types, including coarse thread, fine thread, and metric thread. The thread type will depend on the application and the mating part.

Drive type: 12-point screws require a 12-point socket wrench for installation. The drive type can be specified as SAE or metric.

Finish: 12-point screws can be finished with a variety of coatings, such as black oxide, zinc plating, or chrome plating. The finish can enhance the appearance of the screw and provide additional protection against corrosion.

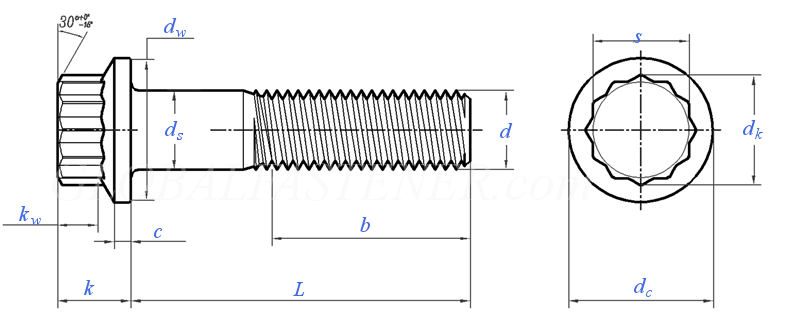

12-point screws are a type of fastener with a unique head design that features twelve points on the head. The head of the screw is typically shaped like two stacked hexagons, with each hexagon having six points. This design provides a secure grip and allows for high torque to be applied to the screw without stripping the head.

12-point screws are commonly used in automotive and aerospace applications, as well as in heavy machinery and construction. They are often made of high-strength materials, such as alloy steel, to withstand heavy loads and high stress.

One advantage of 12-point screws is that they can be tightened or loosened with a socket wrench or spanner, making them easier to work with in tight spaces. However, the design of the head can also make these screws more difficult to center and start than other types of screws, such as Phillips or flat-head screws.

12-point screws, also known as double hexagon screws or flange bolts, are commonly used in a variety of applications where high torque is required. Here are some general specifications for 12-point screws:

Thread type: 12-point screws can have either a fine or coarse thread, depending on the specific application requirements.

Material: 12-point screws can be made from a variety of materials, including steel, stainless steel, brass, and titanium.

Diameter: The diameter of 12-point screws can vary depending on the application. Common diameters include 1/4", 5/16", 3/8", 7/16", 1/2", 5/8", and 3/4".

Length: The length of 12-point screws can also vary depending on the application. Common lengths range from 1/2" to 12" or more.

Head type: 12-point screws have a flanged head, which means they have a wider diameter than the screw shaft. The head can be either circular or hexagonal in shape.

Drive type: 12-point screws require a special tool called a 12-point socket to install and remove them.

Strength: The strength of 12-point screws can vary depending on the material and diameter. Generally, they have a high strength and are designed to withstand heavy loads and high torque.

Finish: 12-point screws can be finished with various coatings to improve their corrosion resistance or appearance. Common finishes include zinc plating, black oxide, and galvanized coatings.

Thread pitch: The thread pitch of 12-point screws can vary depending on the diameter and thread type. Common thread pitches include 20 threads per inch (TPI) for fine threads and 16 TPI for coarse threads.

Tensile strength: The tensile strength of 12-point screws can range from 120,000 to 190,000 pounds per square inch (psi), depending on the material and diameter.

Torque values: The torque values for 12-point screws can vary depending on the diameter, length, and material. Consult a torque chart for specific values.

Applications: 12-point screws are commonly used in heavy machinery, automotive, and aerospace applications where high torque is required. They are also used in construction and structural applications.

• M6 - M100

12 Point Screw Specifications

• IFI-115More information please contact us .

Contact: Sino Special Metal Co., Ltd.

Phone: 86-19527792928

E-mail: sales@ssmsteel.com

Whatsapp:86-19527792928

Add: Mudu town Jinfeng South Road, Wuzhong District, Suzhou City, Jiangsu Province

We chat