Material:Carbon Steel ASTM A105

Pressure Rating:Class 150, 300, 600, 900, 1500, and 2500

Size Range:1/2" to 48"

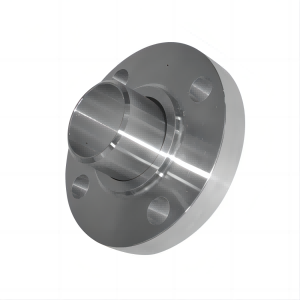

What are ASTM A105 Flanges?

ASME A105 is a specification for forged carbon steel piping components, including flanges. A flange is a disc-shaped fitting that is used to connect pipes, valves, pumps, and other equipment to form a piping system. The ASME A105 flange is designed to meet the high-pressure and high-temperature requirements of various industries, such as oil and gas, chemical, and power generation.

ASTM A105 is a standard specification for carbon steel forgings for piping applications. Here are some of the typical mechanical properties of ASTM A105 material:

| Property | Value |

|---|---|

| Tensile strength | 70 ksi (485 MPa) minimum |

| Yield strength | 36 ksi (250 MPa) minimum |

| Elongation | 22% minimum |

| Reduction of area | 30% minimum |

| Hardness (Brinell) | 187 maximum |

Note that the values above are just for general information. The actual values may vary depending on the specific heat treatment, forging process, and other factors used in the production of ASTM A105 material. It is important to consult the ASTM A105 specification for the full and accurate requirements.

| Parameter | Specification |

|---|---|

| Material | Carbon Steel ASTM A105 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, and 2500 |

| Size Range | 1/2" to 48" |

| Standards | ANSI B16.5, ANSI B16.47 Series A and B |

| Facing Types | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Male and Female (M&F), Tongue and Groove (T&G) |

| Manufacturing | Forged |

| Heat Treatment | Normalize and Temper |

| Chemical Composition | Carbon: 0.35 max; Manganese: 0.60-1.05; Phosphorus: 0.035 max; Sulfur: 0.040 max; Silicon: 0.10-0.35 |

| Mechanical Properties | Tensile Strength: 485 MPa (70,000 psi) min; Yield Strength: 250 MPa (36,000 psi) min; Elongation: 22% min; Reduction of Area: 30% min |

| Applications | Used in industries like oil and gas, petrochemical, power generation, and more for connecting pipelines, valves, and other equipment. |

| Element | Composition (wt. %) |

|---|---|

| Carbon | 0.35 max |

| Manganese | 0.60-1.05 |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

| Silicon | 0.10-0.35 |

Note: The exact chemical composition may vary depending on the manufacturer and specific product requirements. This table provides a general guideline for the chemical composition of A105 carbon steel pipe flanges.

ASTM A105 is a standard specification for forged carbon steel piping components, including flanges. There are several common types of flanges specified in ASTM A105:

ASTM A105 Weld Neck Flange (WNF): This is a flange that has a long tapered hub and is welded to the pipe. It is used in high-pressure, high-temperature applications.

ASTM A105 Slip-On Flange (SOF): This is a flange that slips over the end of the pipe and is then welded in place. It is often used in low-pressure, low-temperature applications.

ASTM A105 Blind Flange (BLF): This is a flange that is used to seal the end of a pipe or valve. It is commonly used in piping systems where maintenance or inspection is required.

ASTM A105 Threaded Flange (THF): This is a flange that has threads on the inside surface, allowing it to be screwed onto a pipe. It is commonly used in low-pressure, non-critical applications.

ASTM A105 Socket Weld Flange (SWF): This is a flange that is welded to the pipe using a socket weld joint. It is often used in high-pressure, high-temperature applications.

ASTM A105 Lap Joint Flange (LJF): This is a flange that is designed to be used with a stub end, which is a pipe fitting that has a flared end. The lap joint flange is used to make a connection between the stub end and the piping system.

These are some of the most common types of flanges specified in ASTM A105, but there are others as well, such as orifice flanges, reducing flanges, and spectacle blinds.

|  |  |

| Welding Neck Flange | Slip-on Flange | Socked Welding Flange |

|  |  |

| Threaded Flange | Blind Flange | Lapped Joint Flange |

ASTM A105N flanges are made from normalized materials, which means that the steel has been heat-treated to improve its mechanical properties, such as tensile strength and toughness. ASTM A105N flanges are typically used in high-pressure and high-temperature applications where the material needs to be able to withstand stress and fatigue.

ASTM A105M flanges are made from materials that have been mechanically tested to ensure they meet specific requirements for low-temperature resistance. These flanges are typically used in applications where the material needs to be able to withstand extreme cold temperatures.

ASTM A105 flanges are made from carbon steel materials and are typically used in low-pressure and low-temperature applications. These flanges are generally the most cost-effective option and are suitable for a wide range of applications where high pressure or temperature is not a concern.

SSM manufactures and supplies ASTM A105 carbon steel flanges in various sizes and materials. We have a strong technical support team and industrial workers to ensure product quality and delivery. Please feel free to call us for inquiries about carbon steel flanges.

Contact: Sino Special Metal Co., Ltd.

Phone: 86-19527792928

E-mail: sales@ssmsteel.com

Whatsapp:86-19527792928

Add: Mudu town Jinfeng South Road, Wuzhong District, Suzhou City, Jiangsu Province

We chat